PRODUCT DESCRIPTION

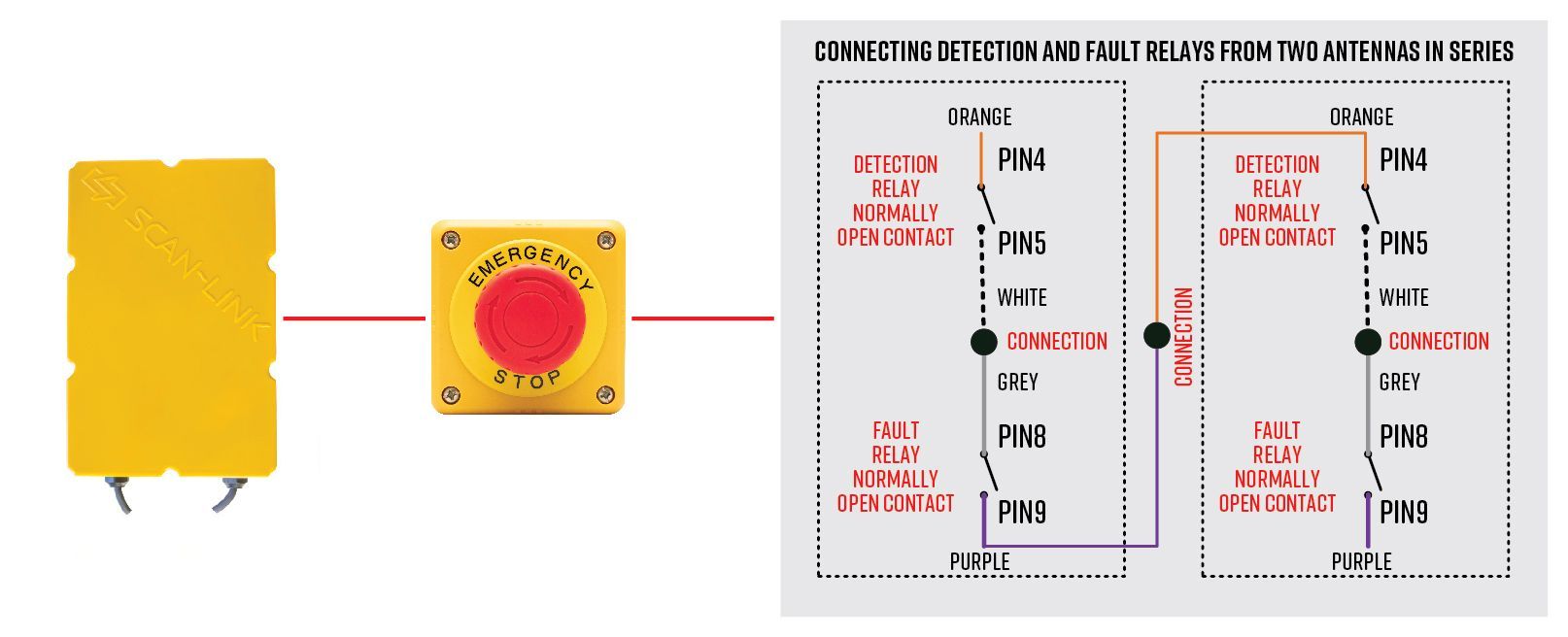

Two antenna units are strategically installed along conveyor systems that feed balers and shredders. These antennas function as safety sensors and integrate directly into your conveyor’s existing E-stop circuit. When a worker wearing SCAN~LINK passive RFID safety apparel enters the detection zone, the system instantly identifies their presence and opens the relay in the E-stop circuit—immediately stopping conveyor movement and preventing accidents. A connected light tower also flashes red and triggers an audible alarm, ensuring rapid awareness for everyone in the area.

With zero false alarms, you keep your operation running efficiently while securing worker safety. SCAN~LINK’s patented technology uses passive RFID tags—requiring no batteries or ongoing maintenance.

CONVEYOR SAFETY CHALLENGES

Industrial conveyor operations pose unique and persistent safety risks. Many facilities grapple with unreliable detection systems that trigger frequent false alarms, leading to unnecessary stoppages and reduced productivity. Other technologies require ongoing maintenance or battery management, adding to operational costs and increasing the risk of failure. Integrating new solutions into existing safety systems can also be complex, often demanding significant time, expertise, and resources.

SCAN~LINK’s Conveyor Unit is engineered to overcome these obstacles. Our passive RFID safety solution delivers reliable personnel detection without false alarms, keeps maintenance demands low with battery-free tags, and integrates seamlessly into existing E-stop safety circuits. This ensures robust, automated protection and operational continuity.

System overview and specifications

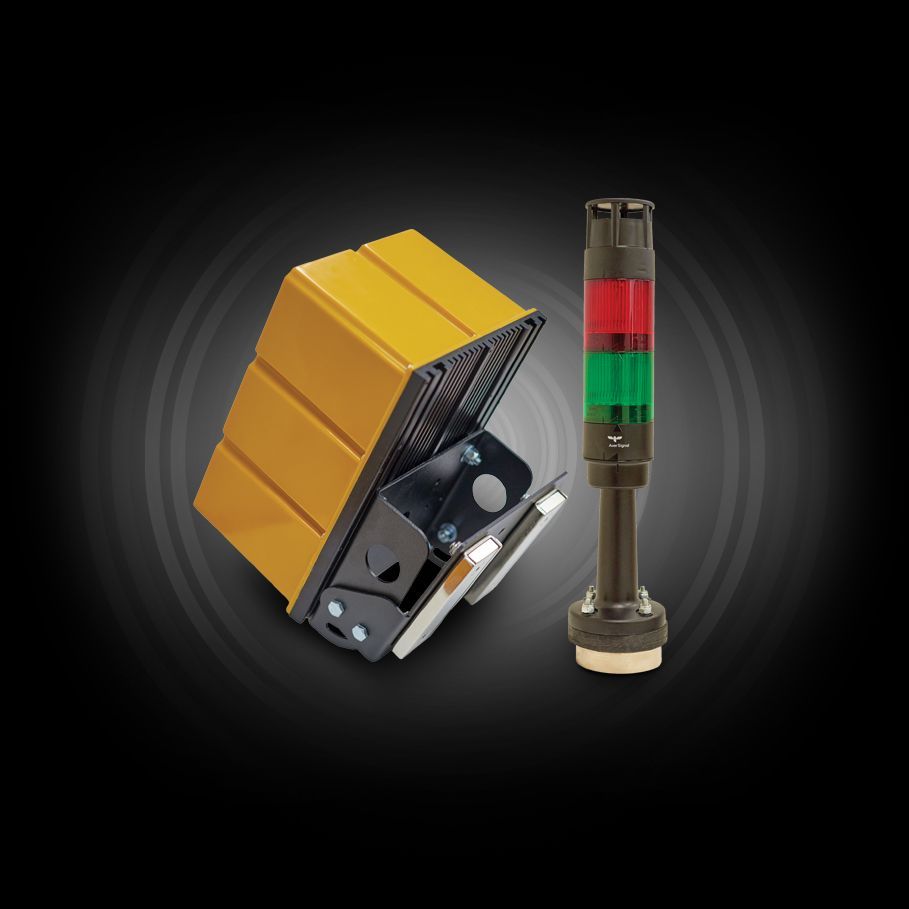

Antenna, bracket, magnets and light tower assembly

Built for demanding industrial environments, the mobile antenna unit is housed in a sealed, weatherproof enclosure for maximum durability. The adjustable, beam-shaping antenna delivers precise zone coverage and is specifically tuned to detect SCAN~LINK’s passive RFID safety apparel. A magnetic bracket enables quick and secure installation on your conveyor line, while the integrated external alarm and light tower provide both visual and audible notifications to enhance hazard awareness for ground personnel.

SPECS:

Operating Voltage: 12VDC - 28VDC nominal

Power Consumption: 7.5-36W

Power Source: PLC or power supply

Temperature Range: -20°C to +80°C

RFID FREQUENCY: 902.3MHz - 927.7MHZ

Wireless Link: 2.4GHZ

Typical Range: Adjustable from 0.5 to 6 meters

RoHS Compliant: Yes

RFID-TAGGED VEST AND HARD HAT KIT

Standard – CSA Z96-02 Class 2 Level 2 ANSI/BISCAY 107-2004

The orange Armour Safety Vest uses a Velcro™ design and features 14 strategically embedded passive RFID tags behind high-visibility 3M™ reflective tape which ensures reliable detection and compliance with safety standards.

Passive RFID tags can also be seamlessly installed in standard hard hats, enabling 360-degree detection. Each tag set is uniquely encoded and double-laminated for superior durability and long-term adhesive performance. With passive technology, you eliminate batteries and maintenance while gaining dependable all-day protection.

RFID-TAGGED LANYARD

Standard – CSA Z96-01 Class 2 Level 2 ANSI/ISEA 107-2004

The orange lanyard features a four-way tear-away design with a 14 strategically positioned RFID tags behind 3M™ reflective tape for reliable detection.

The RFID-Tagged Lanyard is a lightweight alternative to a full safety vest, designed for workers who need comfort and mobility in hot or demanding environments. Ideal for waste and recycling crews, this lanyard reduces heat stress and provides a simple, low-bulk option for staying protected around heavy equipment.

We're Here to Support Your Safety Goals

Contact us to learn how SCAN~LINK’s passive RFID safety solutions improve safety and compliance, or request pricing and a detailed quote tailored to your jobsite.

Contact Us

Contact Us

13 Windward Dr.

Unit 204

Grimsby, Ontario

L3M 4E8

T: 1-905-304-6100

Toll Free: 1-866-554-5582

info@scan-link.com