OIL & GAS

OIL & GAS

Providing RFID Safety Solutions that enhance Human Machine Interface across global operations.

In the inherently hazardous environments of the oil and gas industry, maintaining worker safety amidst complex machinery and extreme conditions is paramount. SCAN~LINK RFID Technology requires no maintenance and is effective in the extreme conditions often found in the Oil & Gas Industry, the low light, the extreme cold and snow, the high heat and dust. Our technology ensures a safer workplace by integrating seamlessly with existing safety protocols, even in the most remote and challenging operational sites.

Providing RFID Safety Solutions that enhance Human Machine Interface across global operations.

In the inherently hazardous environments of the oil and gas industry, maintaining worker safety amidst complex machinery and extreme conditions is paramount. SCAN~LINK RFID Technology requires no maintenance and is effective in the extreme conditions often found in the Oil & Gas Industry, the low light, the extreme cold and snow, the high heat and dust. Our technology ensures a safer workplace by integrating seamlessly with existing safety protocols, even in the most remote and challenging operational sites.

Providing RFID Safety Solutions that enhance Human Machine Interface across global operations.

In the inherently hazardous environments of the oil and gas industry, maintaining worker safety amidst complex machinery and extreme conditions is paramount. SCAN~LINK RFID Technology requires no maintenance and is effective in the extreme conditions often found in the Oil & Gas Industry, the low light, the extreme cold and snow, the high heat and dust. Our technology ensures a safer workplace by integrating seamlessly with existing safety protocols, even in the most remote and challenging operational sites.

SCAN~LINK meets the challenge of harsh environments and high-risk operations, providing RFID safety solutions that safeguard personnel around heavy machinery.

Our services include:

- Professional advice to help determine your needs, and choose the correct product for your application.

- Training for installation and use of our products, including ongoing technical support and troubleshooting.

- No maintenance RFID Safety Apparel which allows for seamless integration into your existing Hard Hats and safety protocols.

SCAN~LINK works with companies that want to:

- Prioritize the highest safety standards in challenging oil and gas environments.

- Reduce the risk of operational hazards from near miss or struck by incidents, improving your HMI (Human Machine Interface).

- Adopt technology that integrates with existing safety measures for immediate impact.

- Cultivate a safety-first culture that aligns with industry best practices and regulatory requirements.

Our services include:

- Professional advice to help determine your needs, and choose the correct product for your application.

- Training for installation and use of our products, including ongoing technical support and troubleshooting.

- No maintenance RFID Safety Apparel which allows for seamless integration into your existing Hard Hats and safety protocols.

SCAN~LINK works with companies that want to:

- Prioritize the highest safety standards in challenging oil and gas environments.

- Reduce the risk of operational hazards from near miss or struck by incidents, improving your HMI (Human Machine Interface).

- Adopt technology that integrates with existing safety measures for immediate impact.

- Cultivate a safety-first culture that aligns with industry best practices and regulatory requirements.

OIL & GAS PRODUCTS

SINGLE NODE UNIT

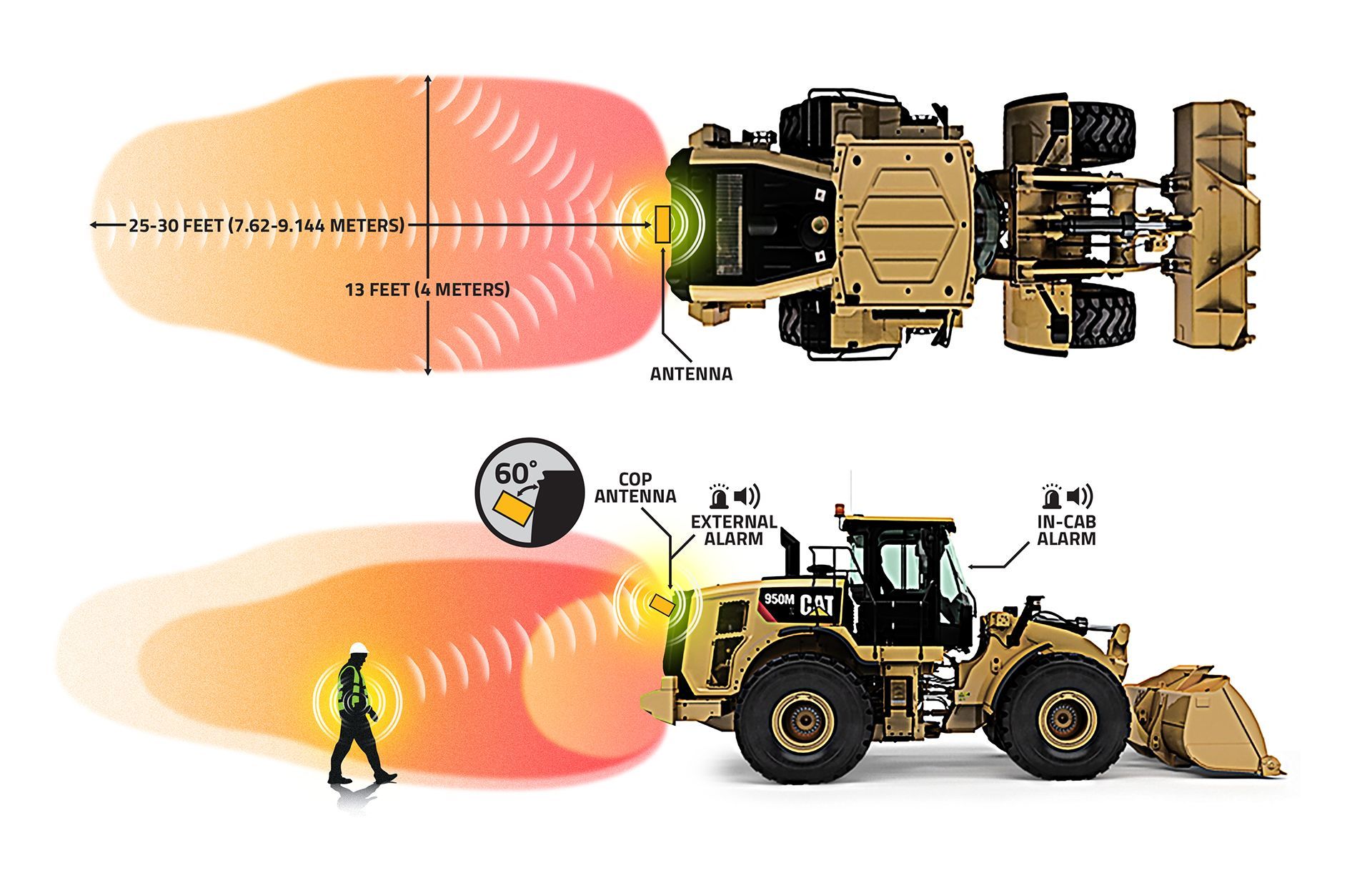

The SCAN~LINK Armour System™ utilizes RFID to alert the operator of the reversing equipment that a ground worker is behind them and extra caution is required, creating a safer work environment.

DUAL NODE UNIT

The SCAN~LINK Armour Dual Node System™ utilizes RFID to alert the operator that a ground worker is in the danger zones. Using 2 Antennas increases the detection zone.

APPAREL & ACCESSORIES

The ground workers and visitors on an Armour Equipped Job Site wearing an Armour RFID tagged Safety Vest and/or Hard Hat will be detected by the SCAN~LINK Armour System™.

SINGLE NODE UNIT

The SCAN~LINK Armour System™ utilizes RFID to alert the operator of the reversing equipment that a ground worker is behind them and extra caution is required, creating a safer work environment.

DUAL NODE UNIT

The SCAN~LINK Armour Dual Node System™ utilizes RFID to alert the operator that a ground worker is in the danger zones. Using 2 Antennas increases the detection zone.

APPAREL & ACCESSORIES

The ground workers and visitors on an Armour Equipped Job Site wearing an Armour RFID tagged Safety Vest and/or Hard Hat will be detected by the SCAN~LINK Armour System™.

REQUEST A QUOTE

SCAN~LINK Technologies Inc.

13 Windward Dr, Unit 204

Grimsby, ON, L3M 4E8

T: 1-905-304-6100

Toll Free: 1-866-554-5582

E: info@scan-link.com

Contact Us

We will get back to you as soon as possible

Please try again later